Understanding the Advantages of Using Octave Ultrasonic Flow Meters for Accurate Liquid and Gas Measurement

Jun 20,2025

Understanding the Advantages of Using Octave Ultrasonic Flow Meters for Accurate Liquid and Gas Measurement

In the world of fluid measurement, precision is key. This is especially true in industries that rely on accurate data for operation and cost efficiency. Octave ultrasonic flow meters have emerged as a leading solution for measuring the flow of liquids and gases with unprecedented accuracy and reliability. This article delves into the advantages of utilizing Octave ultrasonic flow meters, their applications, and how they can enhance efficiency across various sectors.

What Are Octave Ultrasonic Flow Meters?

Octave ultrasonic flow meters employ advanced ultrasonic technology to measure the flow rate of liquids and gases. By using the principle of sound wave propagation, these devices offer a non-intrusive, reliable means of measurement. Understanding how these flow meters work is crucial to appreciating their advantages and applications.

How Do Octave Ultrasonic Flow Meters Work?

The operation of Octave ultrasonic flow meters is based on the time-of-flight method. When an ultrasonic signal is transmitted through a fluid, it travels faster when moving downstream compared to upstream. The difference in transit times, calculated by the device, allows for precise flow measurement. This technique ensures minimal disruption to the flow, making it ideal for various applications.

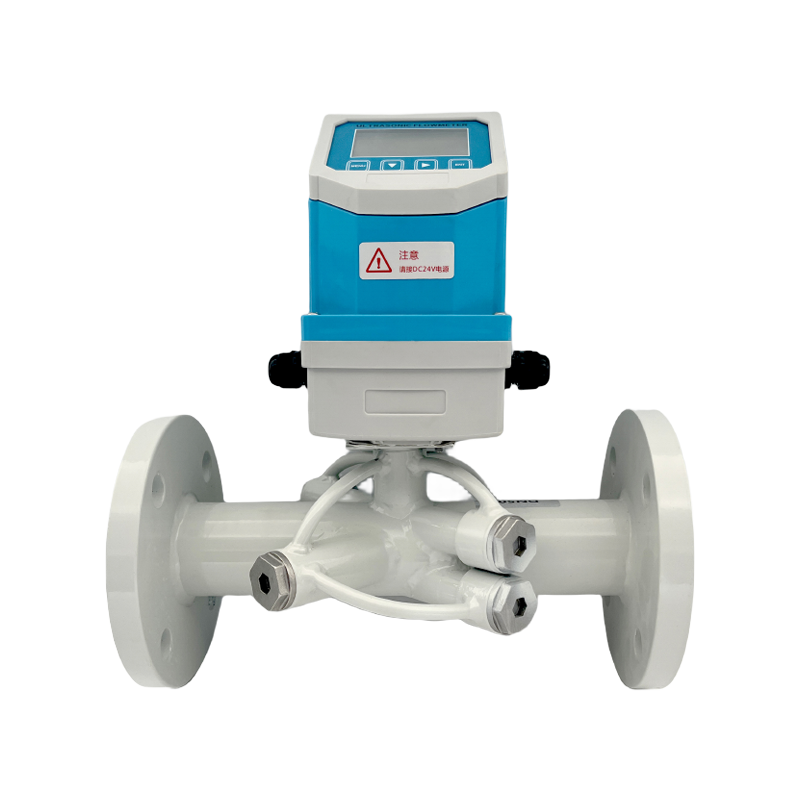

Key Components of Octave Ultrasonic Flow Meters

Key components of these flow meters include:

- Transducers: These emit and receive ultrasonic signals.

- Flow Computer: Analyzes the data from the transducers to calculate the flow rate.

- Display Unit: Provides visual data output for easy monitoring.

Advantages of Using Octave Ultrasonic Flow Meters

Octave ultrasonic flow meters come packed with advantages that make them a preferred choice for many industries. Below are some of the standout benefits:

1. High Accuracy and Reliability

One of the most significant advantages is the high level of accuracy they provide. With an accuracy rating often exceeding ±0.5%, Octave ultrasonic flow meters ensure that measurements are not just precise but also dependable. This precision is essential for industries where even minor discrepancies can lead to substantial financial losses.

2. Non-Intrusive Measurement

Unlike traditional flow meters that require alterations to the piping system, Octave ultrasonic flow meters allow for non-intrusive measurement. This characteristic simplifies installation, minimizes downtime, and eliminates the risk of leaks or pressure drops. As a result, they can be installed with minimal disruption to ongoing operations.

3. Versatility of Application

Octave ultrasonic flow meters are versatile and can measure a wide range of fluids, including:

- Water: Ideal for water treatment, distribution, and wastewater applications.

- Chemicals: Suitable for monitoring corrosive or viscous liquids.

- Gases: Effectively measures various gases, including natural gas and biogas.

This versatility makes them applicable across multiple sectors, including water management, chemical processing, and energy production.

4. Low Maintenance Requirements

Another advantage of Octave ultrasonic flow meters is their low maintenance needs. With no moving parts, these devices reduce wear and tear, leading to increased longevity and decreased maintenance costs. Regular calibration is all that is typically required to ensure continued accuracy.

5. Cost-Effectiveness

While the initial investment may be higher compared to some traditional flow meters, the long-term savings in maintenance, reduced downtime, and improved efficiency can lead to a lower total cost of ownership. This cost-effectiveness is particularly beneficial for businesses looking to optimize their operational budget.

Applications of Octave Ultrasonic Flow Meters

The expansive range of applications for Octave ultrasonic flow meters is a testament to their effectiveness and reliability. Here are a few key areas where they excel:

1. Water and Wastewater Management

In water treatment plants, accurate measurement of water flow is crucial for efficient operation. Octave ultrasonic flow meters help in monitoring water distribution and ensuring compliance with environmental regulations.

2. Oil and Gas Industry

These flow meters provide accurate readings in challenging conditions, such as varying temperatures and pressures common in the oil and gas sector. Their ability to measure gas flow with precision is vital for process optimization and leak detection.

3. Food and Beverage Industry

For the food and beverage sector, maintaining quality standards is paramount. Octave ultrasonic flow meters ensure that liquid measurements are accurate, which is crucial for ingredient batching and quality control.

4. Chemical Processing

In chemical processing, precise flow measurements are essential for maintaining safe and efficient operations. The non-intrusive nature of these flow meters is particularly beneficial in handling hazardous or corrosive substances.

Comparing Octave Ultrasonic Flow Meters to Traditional Flow Meters

When considering flow measurement technologies, it's essential to compare Octave ultrasonic flow meters with traditional options like mechanical flow meters or differential pressure flow meters. Here are some key differences:

1. Measurement Technique

While traditional flow meters often rely on mechanical components or differential pressure, Octave ultrasonic flow meters utilize sound waves. This results in higher accuracy and fewer mechanical failures.

2. Installation and Maintenance

Traditional flow meters may require significant alterations to existing piping systems, leading to increased installation time and costs. In contrast, ultrasonic flow meters can be quickly installed without interrupting the flow, and their low maintenance needs reduce long-term operational costs.

3. Application Range

Traditional flow meters may be limited in the types of fluids they can measure effectively. In contrast, Octave ultrasonic flow meters can accurately measure a diverse range of liquids and gases, making them more versatile.

Understanding the Technology Behind Octave Ultrasonic Flow Meters

The technology behind Octave ultrasonic flow meters is grounded in advanced engineering and physics. By understanding the core principles, users can better appreciate the benefits of this technology.

1. Time-of-Flight Measurement

As mentioned earlier, the time-of-flight technique is fundamental to the operation of these meters. The detection of sound wave propagation differences allows for precise calculations, ensuring accurate flow rates.

2. Digital Signal Processing (DSP)

Octave ultrasonic flow meters often utilize sophisticated DSP algorithms to enhance measurement accuracy and reduce noise interference. This technology enables the device to adapt to varying flow conditions, providing reliable data even in challenging environments.

Factors to Consider When Choosing an Octave Ultrasonic Flow Meter

When selecting an Octave ultrasonic flow meter, various factors must be considered to ensure optimal performance for specific applications:

1. Fluid Characteristics

Understanding the physical properties of the fluid being measured, such as viscosity and temperature, is essential for selecting the right flow meter. Some models are specifically designed for challenging fluids.

2. Installation Environment

The installation environment, including pipe size, pressure, and potential ambient conditions, can affect the performance of the flow meter. Evaluating these factors will help in choosing the most suitable model.

3. Accuracy Requirements

Different applications may demand varying levels of accuracy. It’s crucial to identify the required accuracy level to select the appropriate meter that meets operational needs.

Conclusion

Octave ultrasonic flow meters represent a significant advancement in flow measurement technology, offering numerous advantages over traditional flow meters. From high accuracy and reliability to low maintenance and versatility of application, these devices are well-suited for a variety of industries. As businesses continue to prioritize efficiency and precision, the adoption of Octave ultrasonic flow meters is likely to grow, solidifying their place as a preferred choice for fluid measurement. By understanding these advantages and how to select the right flow meter, organizations can optimize their operations and ensure compliance with industry standards.

FAQs

1. What is the primary advantage of using Octave ultrasonic flow meters?

The primary advantage is their high accuracy and reliability in measuring the flow of liquids and gases without intruding into the flow system.

2. How do Octave ultrasonic flow meters differ from traditional flow meters?

They differ in measurement techniques, installation requirements, and versatility, with ultrasonic meters being non-intrusive and applicable to a wider range of fluids.

3. Can Octave ultrasonic flow meters measure both liquids and gases?

Yes, these flow meters are designed to accurately measure a variety of liquids and gases, making them suitable for multiple applications.

4. What industries benefit most from Octave ultrasonic flow meters?

Key industries include water management, oil and gas, food and beverage, and chemical processing.

5. What maintenance is required for Octave ultrasonic flow meters?

The maintenance typically involves regular calibration and occasional cleaning, with minimal maintenance needed due to the absence of moving parts.

PREVIOUS: