Maximizing Efficiency: The Role of Octave Ultrasonic Flow Meters in Liquid Measurement

Jun 22,2025

Maximizing Efficiency: The Role of Octave Ultrasonic Flow Meters in Liquid Measurement

Table of Contents

- Introduction to Octave Ultrasonic Flow Meters

- Understanding Ultrasonic Flow Meters

- The Technology Behind Octave Ultrasonic Flow Meters

- Advantages of Octave Ultrasonic Flow Meters

- Applications in Various Industries

- Comparison with Traditional Flow Meters

- Installation and Maintenance of Ultrasonic Flow Meters

- The Future of Liquid Measurement Technology

- Conclusion

- FAQs

Introduction to Octave Ultrasonic Flow Meters

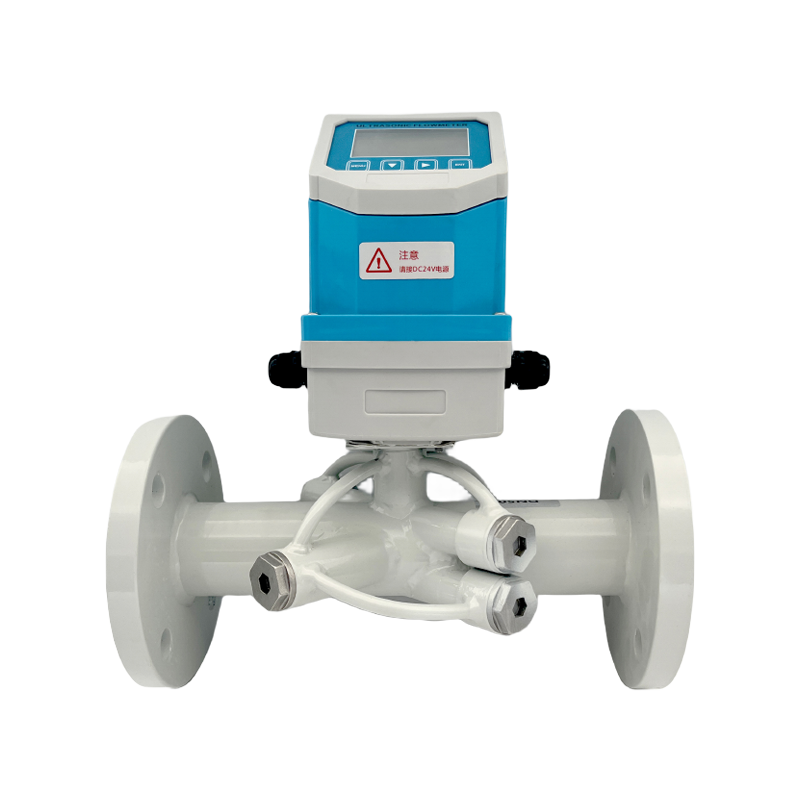

In the realm of liquid measurement, precision and efficiency are paramount. **Octave Ultrasonic Flow Meters** represent a leap forward in ensuring these qualities. By harnessing advanced ultrasonic technology, these meters provide accurate and reliable measurements for a wide range of liquid applications. In this article, we will delve into how Octave Ultrasonic Flow Meters enhance efficiency in liquid measurement, exploring their technology, advantages, and applications across various industries.

Understanding Ultrasonic Flow Meters

Ultrasonic flow meters operate on a simple yet effective principle: they use sound waves to measure the velocity of a liquid. By sending ultrasonic signals through the liquid, these meters can accurately calculate flow rates based on the time it takes for the sound waves to travel to a receiver. This method eliminates the need for moving parts, which is a significant advantage over traditional mechanical flow meters.

**Key Components** of ultrasonic flow meters include:

- **Transducers:** These are the devices that emit and receive ultrasonic signals.

- **Signal Processor:** This component calculates the flow rate by analyzing the time difference between the emitted and received signals.

- **Display Unit:** This shows real-time flow measurements for easy monitoring.

The Technology Behind Octave Ultrasonic Flow Meters

The technology utilized in Octave Ultrasonic Flow Meters is at the forefront of liquid measurement innovation. Employing dual-path or multi-path configurations, Octave meters can significantly enhance measurement accuracy by reducing the effects of turbulence and viscosity.

**Key Technologies Include:**

1. **Time-of-Flight Measurement:** This method calculates the time taken for ultrasonic waves to travel with and against the flow, providing precise velocity measurements.

2. **Digital Signal Processing:** Advanced algorithms analyze the received signals, filtering out noise and enhancing measurement accuracy.

3. **Temperature and Pressure Compensation:** These meters include features that adjust readings based on the liquid’s temperature and pressure, ensuring consistent accuracy across varying conditions.

Advantages of Octave Ultrasonic Flow Meters

The adoption of Octave Ultrasonic Flow Meters comes with **numerous advantages** that make them a preferred choice in many industries:

1. **High Accuracy:** These meters boast an accuracy of up to ±0.5%, allowing for precise measurements critical in applications like chemical processing and water treatment.

2. **Wide Measurement Range:** They can measure a variety of liquids, including those that are viscous or contain solids, making them versatile.

3. **No Moving Parts:** The lack of moving components results in lower maintenance requirements and longer service life compared to mechanical flow meters.

4. **Installation Flexibility:** Ultrasonic flow meters can be installed in various orientations and locations, including temporary setups for testing purposes.

5. **Cost-Effective:** While the initial investment may be higher, the long-term savings from reduced maintenance and operational efficiency can offset these costs.

Applications in Various Industries

Octave Ultrasonic Flow Meters have found applications across diverse industries, each benefiting from enhanced measurement capabilities.

1. Water and Wastewater Treatment

In water treatment facilities, accurate flow measurement is crucial for managing resources and ensuring regulatory compliance. Ultrasonic flow meters help monitor flow rates of influent and effluent, improving process control and efficiency.

2. Chemical Processing

Chemical manufacturing requires precise flow measurements to maintain product quality and safety. Octave Ultrasonic Flow Meters enable accurate dosing of raw materials and monitoring of reaction conditions.

3. Oil and Gas

In the oil and gas sector, measuring the flow of crude oil and natural gas is essential for production efficiency. Ultrasonic flow meters provide reliable measurements in challenging conditions, including high pressures and varying temperatures.

4. Food and Beverage

The food and beverage industry demands strict compliance with safety standards. Ultrasonic flow meters are used to ensure accurate measurements of ingredients and maintain consistent product quality throughout the production process.

5. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, accurate flow measurement enhances energy efficiency and system performance. Ultrasonic meters help monitor the flow of water and refrigerants, ensuring optimal operation.

Comparison with Traditional Flow Meters

When evaluating flow measurement technologies, it’s essential to compare the benefits of Octave Ultrasonic Flow Meters against traditional flow meters, such as positive displacement and turbine flow meters.

Accuracy and Reliability

Octave Ultrasonic Flow Meters outperform traditional meters in accuracy, especially in fluctuating flow conditions. Their non-invasive design ensures that they remain unaffected by changes in viscosity or density.

Maintenance Needs

Traditional flow meters often require regular maintenance due to their mechanical components, which can wear out over time. In contrast, ultrasonic flow meters require minimal upkeep, significantly reducing downtime and maintenance costs.

Installation Flexibility

While traditional flow meters often require specific orientations and mounting positions, ultrasonic flow meters offer greater flexibility, allowing for installation in various locations without compromising accuracy.

Installation and Maintenance of Ultrasonic Flow Meters

Proper installation and maintenance are crucial for maximizing the efficiency of Octave Ultrasonic Flow Meters.

Installation Guidelines

1. **Site Survey:** Conduct a thorough survey to determine the best installation location, considering factors like pipe size, location of transducers, and accessibility.

2. **Calibration:** Ensure that the flow meter is calibrated according to manufacturer specifications. Calibration helps maintain measurement accuracy.

3. **Orientation:** Install the meter in the recommended orientation to prevent issues such as trapped air or sediment accumulation.

Maintenance Best Practices

1. **Regular Inspections:** Schedule periodic inspections to ensure that the transducers and signal processors are functioning correctly.

2. **Cleaning:** Keep the flow meter clean to prevent buildup that may interfere with measurements.

3. **Software Updates:** If applicable, regularly update the device's software to benefit from enhanced algorithms and features.

The Future of Liquid Measurement Technology

As industries continue to evolve, the demand for more efficient and accurate measurement solutions will drive advancements in ultrasonic flow meter technology. Future developments may include:

- **Integration with IoT:** Connecting flow meters to the Internet of Things (IoT) will enable real-time monitoring and data analysis across multiple locations.

- **Enhanced Data Analytics:** Leveraging big data and machine learning to predict maintenance needs and optimize flow processes.

- **Smart Calibration Techniques:** Automating calibration processes to improve accuracy and reduce installation time.

Conclusion

Octave Ultrasonic Flow Meters are transforming the landscape of liquid measurement through their advanced technology and numerous benefits. With high accuracy, low maintenance requirements, and versatility across multiple industries, these meters stand as a reliable solution for modern flow measurement challenges. As technology continues to advance, we can expect Octave Ultrasonic Flow Meters to play an even more significant role in optimizing liquid measurement efficiency.

FAQs

1. What is the primary advantage of using Octave Ultrasonic Flow Meters?

**The primary advantage** is their high accuracy and reliability, providing precise liquid measurements without the need for moving parts.

2. Can Octave Ultrasonic Flow Meters be used for both clean and dirty liquids?

Yes, these meters are versatile and can measure both clean and dirty liquids, including those with particulates or varying viscosities.

3. How do I maintain my Octave Ultrasonic Flow Meter?

Maintaining your flow meter involves regular inspections, cleaning, and ensuring software updates are applied where applicable.

4. Are Octave Ultrasonic Flow Meters suitable for high-temperature applications?

Yes, Octave Ultrasonic Flow Meters are designed to handle a range of temperatures, making them suitable for various high-temperature applications.

5. What industries benefit most from Octave Ultrasonic Flow Meters?

Industries such as water treatment, chemical processing, oil and gas, food and beverage, and HVAC systems significantly benefit from the use of Octave Ultrasonic Flow Meters.

TAG:

PREVIOUS: