Troubleshooting Tips for Your PT878 Ultrasonic Flow Meter: Essential Guidance for Accurate Measurements

Jun 28,2025

Troubleshooting Tips for Your PT878 Ultrasonic Flow Meter: Essential Guidance for Accurate Measurements

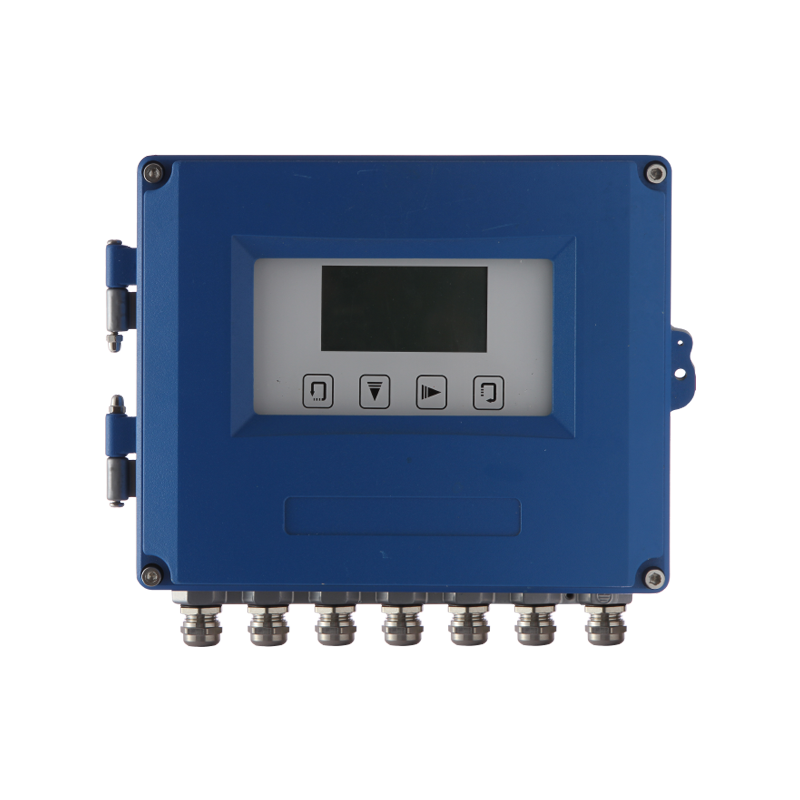

The PT878 Ultrasonic Flow Meter is a highly regarded instrument in the realm of flow measurement. Known for its reliability and accuracy, it is essential that users understand common troubleshooting techniques to address any issues that may arise. In this guide, we will delve into the most prevalent problems encountered with the PT878, along with practical solutions and tips to maintain optimal performance. By following these guidelines, you can ensure that your measurements remain precise and your operations run smoothly.

Table of Contents

- Understanding the PT878 Ultrasonic Flow Meter

- Common Issues and Their Symptoms

- Troubleshooting Guide for PT878

- Issue 1: Signal Loss

- Issue 2: Inaccurate Measurements

- Issue 3: Display Problems

- Issue 4: Battery-Related Issues

- Preventative Maintenance Tips

- When to Seek Professional Help

- Frequently Asked Questions

- Conclusion

Understanding the PT878 Ultrasonic Flow Meter

The PT878 Ultrasonic Flow Meter operates on the principle of measuring the transit time of ultrasonic signals as they travel through a fluid. It is designed to measure both clean and dirty liquids, making it versatile for various applications, including water treatment, chemical processing, and HVAC systems. Understanding the functionality and capabilities of this device is vital for effectively troubleshooting any issues that may arise.

Key Features of the PT878 Ultrasonic Flow Meter

- Non-Intrusive Measurement: The PT878 can be installed without interrupting flow, ensuring minimal disruption to operations.

- Wide Measurement Range: It can accurately measure flow rates across a broad spectrum of velocities.

- User-Friendly Interface: The intuitive display and controls allow for easy operation and navigation.

Common Issues and Their Symptoms

Despite its robust design, the PT878 Ultrasonic Flow Meter may encounter issues that can affect its performance. Recognizing these problems early on can save time and resources. Below are some of the most common issues users may face:

1. Signal Loss

Signal loss occurs when the flow meter fails to receive or send ultrasonic signals effectively. This can lead to incomplete readings or measurement failures.

2. Inaccurate Measurements

Inaccurate readings can stem from various factors, including improper installation, changes in fluid properties, or external interference.

3. Display Problems

Problems with the display, such as flickering or being unresponsive, can hinder the user’s ability to read measurements accurately.

4. Battery-Related Issues

Battery problems can lead to sudden shutdowns or erratic performance, particularly in portable models.

Troubleshooting Guide for PT878

Having identified the common issues, let’s explore practical troubleshooting steps for each problem category.

Issue 1: Signal Loss

Signal loss can be caused by numerous factors, including poor transducer placement, excessive flow conditions, or obstructions in the line. To troubleshoot:

- Check Transducer Alignment: Ensure that the transducers are properly aligned and securely mounted, as misalignment can lead to signal attenuation.

- Inspect for Obstructions: Look for any debris or physical barriers that could block the ultrasonic path.

- Verify Flow Conditions: Ensure that the flow conditions (velocity, temperature, etc.) are within the meter’s operational limits.

Issue 2: Inaccurate Measurements

Inaccurate measurements may require multiple checks and adjustments:

- Recalibrate the Meter: Follow the manufacturer’s instructions for recalibrating the flow meter to ensure accuracy.

- Review Fluid Properties: Changes in fluid density or viscosity can affect readings. Adjust settings accordingly.

- Examine Installation: Confirm that the installation follows the recommended guidelines, including pipe diameter and length specifications.

Issue 3: Display Problems

When faced with display issues, consider the following steps:

- Reset the Unit: Turn off the flow meter and restart it to see if the display returns to normal.

- Check Power Source: Ensure that the battery or power supply is functioning correctly. Replace batteries if necessary.

- Inspect Connections: Look for loose or damaged cables that may be affecting display performance.

Issue 4: Battery-Related Issues

Battery problems can disrupt operation, requiring troubleshooting as follows:

- Replace Batteries: Regularly check and replace batteries to prevent unexpected shutdowns.

- Check Battery Contacts: Ensure that battery terminals are clean and free of corrosion to maintain a good connection.

- Evaluate Power Consumption: If battery life is consistently short, consider reviewing the flow meter’s settings and usage frequency.

Preventative Maintenance Tips

Maintaining your PT878 Ultrasonic Flow Meter is crucial to minimizing issues and ensuring accurate readings. Here are some tips for effective preventative maintenance:

- Regular Calibration: Schedule regular calibration checks to ensure measurement accuracy.

- Clean the Transducers: Periodically clean the transducers to prevent buildup that can interfere with signal transmission.

- Monitor Environmental Conditions: Keep the flow meter in suitable environmental conditions to avoid damage or inaccuracies.

When to Seek Professional Help

While many issues can be resolved through troubleshooting, some problems may require professional assistance. If you encounter persistent issues even after following the troubleshooting steps, it’s advisable to consult a qualified technician or the manufacturer for further guidance.

Frequently Asked Questions

1. How often should I calibrate my PT878 Ultrasonic Flow Meter?

Calibration should be performed at least once a year or more frequently if the device is subject to harsh conditions or significant changes in fluid properties.

2. Can I install the PT878 Ultrasonic Flow Meter myself?

Yes, as long as you follow the manufacturer’s installation guidelines carefully. Ensure that you have the necessary tools and knowledge to perform the installation correctly.

3. What should I do if my flow meter is not displaying any readings?

Check the power source, ensure proper installation, and verify that there are no obstructions in the flow path. If issues persist, consider recalibrating the device.

4. Is it necessary to use specific transducers for different fluid types?

Yes, using the correct transducers is essential for accurate measurements, as different fluids may require specific transducer types for optimal performance.

5. How can I extend the battery life of my PT878 Ultrasonic Flow Meter?

Regularly check battery health, reduce use of backlighting when not needed, and consider turning off the device during prolonged periods of inactivity.

Conclusion

Understanding the common issues and troubleshooting techniques for your PT878 Ultrasonic Flow Meter is essential for maintaining accuracy and efficiency in your operations. By following the outlined tips and regularly performing preventative maintenance, you can minimize downtime and ensure reliable measurements. When in doubt, do not hesitate to seek professional assistance to keep your flow meter functioning optimally. Proper care and proactive troubleshooting will extend the life of your instrument, ensuring that you receive the best performance for your measurements.