The Future of Fluid Measurement: Exploring Octave Ultrasonic Flow Meters

Jul 14,2025

The Future of Fluid Measurement: Exploring Octave Ultrasonic Flow Meters

Table of Contents

- 1. Introduction to Fluid Measurement Technologies

- 2. Understanding Octave Ultrasonic Flow Meters

- 3. How Octave Ultrasonic Flow Meters Work

- 4. Advantages of Octave Ultrasonic Flow Meters

- 5. Applications of Octave Ultrasonic Flow Meters

- 6. Challenges and Considerations in Choosing Flow Meters

- 7. The Future of Fluid Measurement Technology

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Fluid Measurement Technologies

In today's fast-paced industrial landscape, accurate fluid measurement is fundamental to operational efficiency, safety, and compliance. **Fluid measurement technologies** have evolved significantly over the years, offering various solutions tailored to different applications. Among these, **Octave Ultrasonic Flow Meters** stand out due to their accuracy, reliability, and versatility. As industries increasingly demand precise measurements for both gas and liquid applications, understanding the nuances of these innovative devices is essential.

2. Understanding Octave Ultrasonic Flow Meters

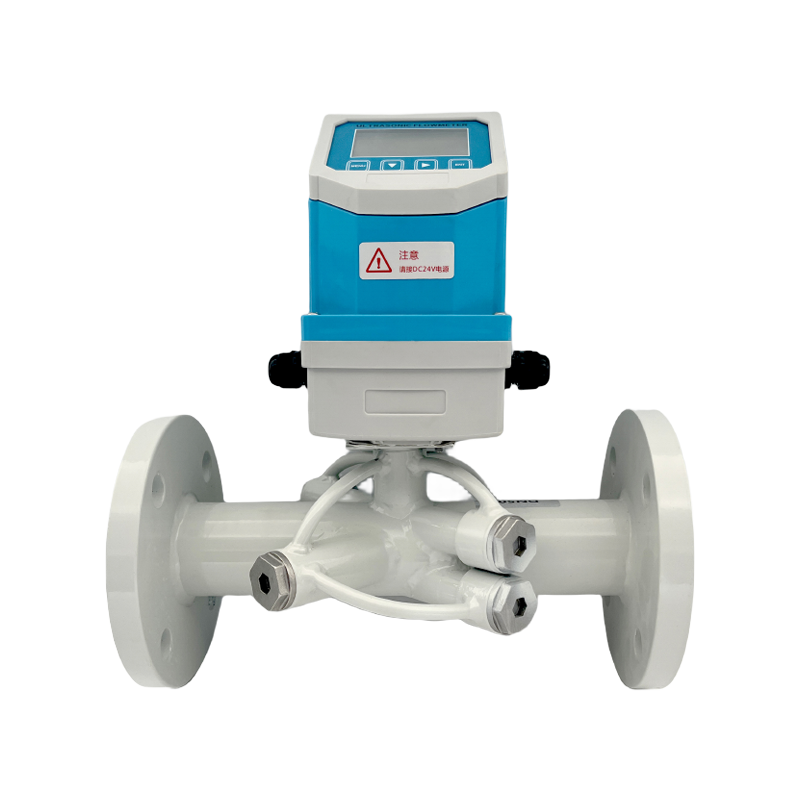

**Octave Ultrasonic Flow Meters** utilize the principle of ultrasonic sound waves to measure the flow rate of fluids. Unlike traditional flow meters, which rely on mechanical components, ultrasonic meters are non-intrusive and have no moving parts. This characteristic makes them less prone to wear and tear, ensuring longevity and consistent performance.

The term "octave" refers to the specific frequency range of the ultrasonic waves used in the measurement process. These flow meters typically operate at frequencies from 1 MHz to several MHz, enabling them to provide highly accurate measurements across a variety of flow conditions.

3. How Octave Ultrasonic Flow Meters Work

The functionality of Octave Ultrasonic Flow Meters can be explained through two main measurement techniques: **transit-time** and **Doppler**.

3.1 Transit-Time Measurement

In **transit-time measurement**, ultrasonic signals are sent through the fluid in both upstream and downstream directions. The flow meter calculates the time difference between the two signals. A higher flow rate results in a greater time difference, which the meter translates into a precise flow measurement. This method is highly effective for clean, non-aerated fluids.

3.2 Doppler Measurement

**Doppler measurement**, on the other hand, relies on the reflection of ultrasonic waves off suspended particles or bubbles within the fluid. This technique is particularly useful for measuring flow rates in fluids that contain solid particles or have non-homogeneous compositions. The frequency shift of the reflected waves provides the necessary data to ascertain the flow rate.

4. Advantages of Octave Ultrasonic Flow Meters

Octave Ultrasonic Flow Meters come with a host of advantages that make them a preferred choice for many industries:

4.1 High Accuracy

One of the standout features of **Octave Ultrasonic Flow Meters** is their high degree of accuracy. With typical measurement errors less than ±1%, these devices ensure precise flow readings, which are critical for process control and billing.

4.2 Non-Intrusive Design

The non-intrusive nature of these flow meters means they can be installed without interrupting the flow of the fluid. This not only reduces downtime but also eliminates potential contamination of the fluid being measured.

4.3 Low Maintenance

The absence of moving parts in Octave Ultrasonic Flow Meters translates to minimal maintenance requirements. Users can expect a longer lifespan and reduced operational costs over time.

4.4 Versatility

These flow meters can measure a wide range of fluids, including clean water, wastewater, and even some corrosive liquids. Their versatility makes them suitable for various industries, from water treatment to petrochemical processing.

4.5 Wide Measurement Range

Octave Ultrasonic Flow Meters can accommodate both low and high flow rates, providing flexibility for different applications. This wide measurement range ensures that they can perform effectively under varying conditions.

5. Applications of Octave Ultrasonic Flow Meters

The versatility of Octave Ultrasonic Flow Meters allows them to be employed in numerous applications across various sectors:

5.1 Water and Wastewater Management

In water treatment plants, these flow meters are essential for monitoring flow rates and ensuring compliance with environmental regulations. Their ability to measure both clean and contaminated water makes them invaluable in this sector.

5.2 Oil and Gas Industry

In the oil and gas industry, Octave Ultrasonic Flow Meters are used for measuring crude oil, gas, and refined products. Their non-intrusive design minimizes the risk of leaks and contamination, which is critical in this sector.

5.3 Food and Beverage

The food and beverage industry requires high levels of hygiene and accuracy in measuring fluid flows. These flow meters can handle various liquids while ensuring compliance with health regulations.

5.4 Chemical Processing

Chemical plants benefit from the accuracy and versatility of Octave Ultrasonic Flow Meters when measuring corrosive or hazardous fluids. Their durability and low maintenance requirements are key advantages in this demanding environment.

5.5 HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, these flow meters help monitor and control the flow of both water and air, ensuring optimal system performance.

6. Challenges and Considerations in Choosing Flow Meters

While Octave Ultrasonic Flow Meters offer numerous benefits, there are challenges and considerations to keep in mind:

6.1 Installation Requirements

Proper installation is crucial for accurate measurements. Users must ensure that the flow meter is installed in a straight section of piping to avoid turbulent flow, which can lead to erroneous readings.

6.2 Fluid Characteristics

The effectiveness of these flow meters can be influenced by the characteristics of the fluid being measured, such as temperature, pressure, and viscosity. Understanding these variables is essential for optimal performance.

6.3 Initial Costs

Although Octave Ultrasonic Flow Meters can save money in the long run, their initial acquisition cost can be higher than traditional flow measurement devices. However, the potential for lower maintenance costs often offsets this investment.

7. The Future of Fluid Measurement Technology

The future of fluid measurement technology is promising, with advancements in sensor technology, digital integration, and data analytics.

7.1 Integration with IoT

The integration of Octave Ultrasonic Flow Meters with the Internet of Things (IoT) enables real-time data monitoring and analytics. This development allows businesses to optimize their processes, reduce waste, and enhance decision-making.

7.2 Smart Sensors

The evolution of smart sensors will lead to even more accurate and reliable flow measurements. These sensors can self-calibrate, providing users with enhanced performance and fewer manual adjustments.

7.3 Predictive Maintenance

As data analytics becomes more sophisticated, the ability to predict maintenance needs will improve. Companies can minimize downtime and extend the lifespan of their flow measurement devices by proactively addressing potential issues.

8. Frequently Asked Questions (FAQs)

8.1 What is the primary advantage of using Octave Ultrasonic Flow Meters?

**The primary advantage** of Octave Ultrasonic Flow Meters is their high accuracy and non-intrusive design, which minimizes maintenance and operational costs.

8.2 Can Octave Ultrasonic Flow Meters measure both liquids and gases?

**Yes**, Octave Ultrasonic Flow Meters are versatile and can accurately measure both liquid and gas flow rates, making them suitable for a wide range of applications.

8.3 How do I choose the right flow meter for my application?

When choosing a flow meter, consider factors such as the type of fluid, flow rate, installation requirements, and budget. Consulting with a flow measurement expert can also provide valuable insights.

8.4 Are Octave Ultrasonic Flow Meters suitable for high-temperature applications?

**Many** Octave Ultrasonic Flow Meters are designed to withstand high temperatures, but it’s essential to check the specifications of each model to ensure compatibility with your application.

8.5 What maintenance is required for Octave Ultrasonic Flow Meters?

Due to their non-intrusive design and lack of moving parts, Octave Ultrasonic Flow Meters require minimal maintenance. Regular calibration and periodic checks for accuracy are recommended.

9. Conclusion

As industries continue to evolve, the demand for precise fluid measurement technology will only increase. **Octave Ultrasonic Flow Meters** represent a significant advancement in flow measurement, offering unparalleled accuracy and reliability. Their versatility across various applications, combined with ongoing technological advancements, ensures they will play a crucial role in the future of fluid measurement. By understanding their functionality, advantages, and potential challenges, businesses can make informed decisions that enhance operational efficiency and ensure compliance in an ever-changing landscape. Embracing this technology is not just an investment in measurement accuracy; it is a strategic move towards achieving operational excellence and sustainability.

TAG:

PREVIOUS: